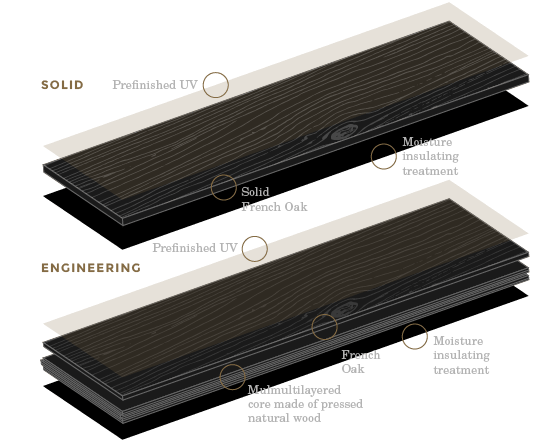

solid floor vs engineering floor

SOLID

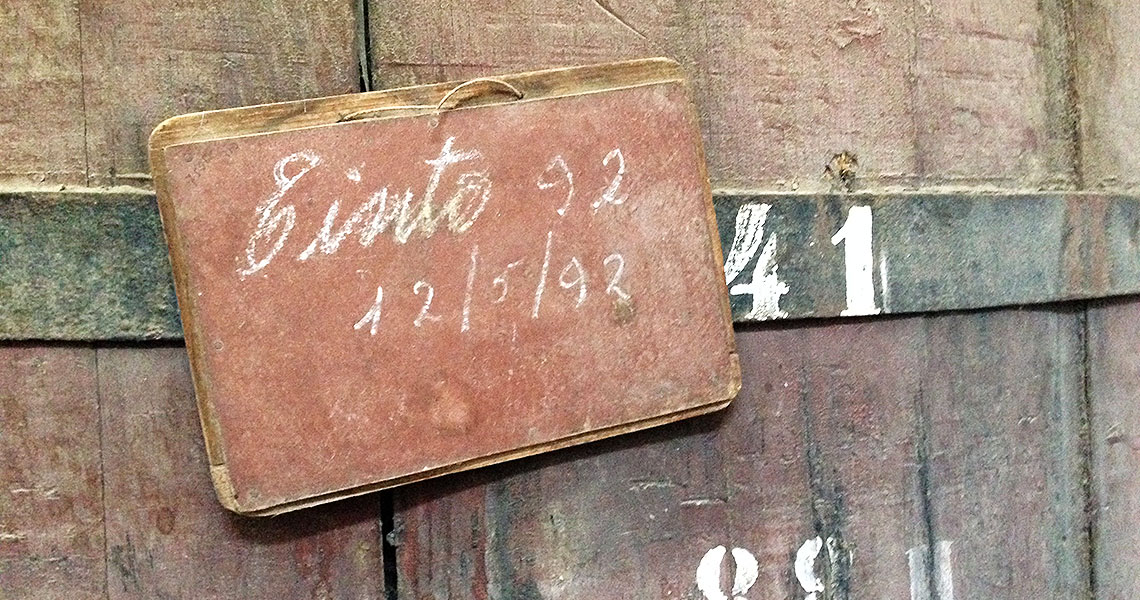

It is made with 100% of French Oak taken from old barrels from the Province of Mendoza, Argentina.

ENGINEERING

It combines a multilayered core made of pressed natural wood, with a top layer of 3 or 6 mm made of French Oak taken from old barrels from the Province of Mendoza, Argentina. Thanks to a meticulous production process, each component of this group is prepared to create a perfect balanced floor, resulting in a high dimensional and torsional stability. Such stability is superior to the one of the solid floor, but with the same durability as the latter.

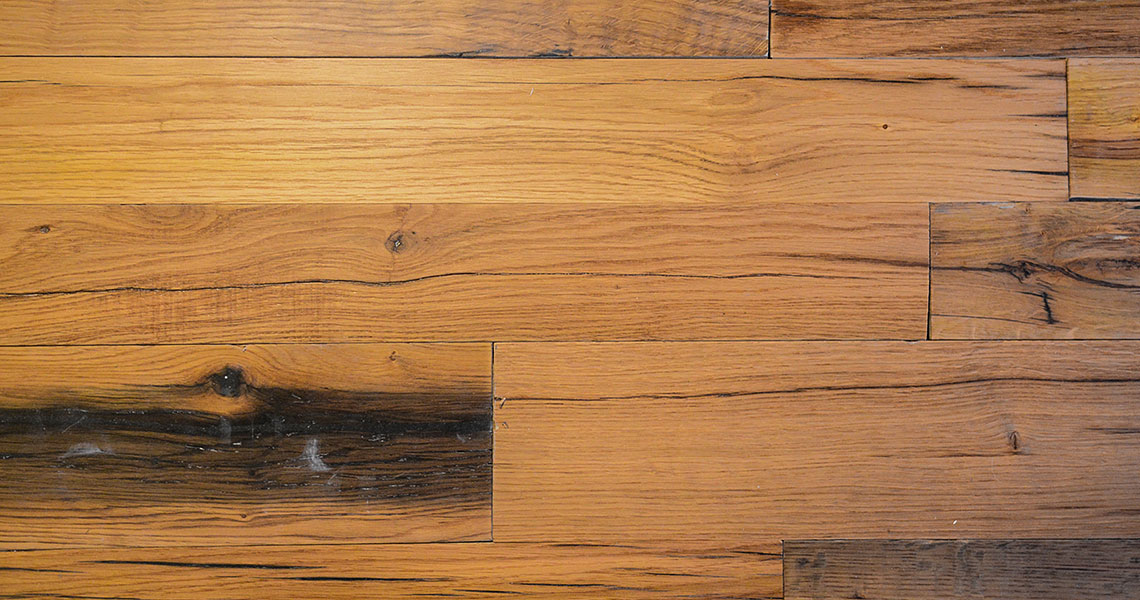

Size of the tables: thanks to the use of barrels with a capacity of more than 35,000 litres, we can obtain floors of up to 18.4 cm wide and 220 cm high, which perfectly complement each other with other smaller tables.

Appearance and finishing process

The colors and grains of the French Oak are mixed with the reddish tones produced by the wine which has been inside the barrels for decades. Cracks, traces of repairs and nail are also mixed with the dark tones… all of them showing and being witnesses of its disuse during many years, of its assembly process, of its reparation and internal burn which was carried out to preserve and maintain the barrels.

Our floors are history: to preserve them we use high tech luster systems, considering these essential features:

Easy installation and maintenance:

Our floors are lustered in the Company, what simplifies and speeds the process of installation, as it is not necessary to apply any other process in the place where they would be installed. The clean, hypoallergenic and healthy finishing process makes dirt adhesion difficult.

Clearness and colors:

Our lustering process makes up a clearness layer that plants the natural colors of the product firmly, without modifying it. It protects the wood from the UV rays, decreasing the changes of colors produced by the lengthy exposure to sun rays.

Durability:

Our floors have a high wear resistance. A flexible luster allows us to preserve the original appearance of the floor and to avoid its cracking.

Colors and unique tones:

Our floors do not need special inks or processes. They are truly ancient. There are not standardized production processes: each table is unique and unrepeatable, as well as its cracks, traces and colors.

collocation process

The wooden floors of Lost barrels are packed up in boxes with tables of different sizes. Each size has been carefully planned to optimize the compatibility and to enable different collocation methods.

box

An easy and quick collocation method, with several widths and lengths. We use the combinations that are preset in the product box.

line

This type of distribution is based on a linear placement of tables with the same width. Thanks to the wide variety of measures, an heterogeneous effect is achieved. However, as the same time, it conserves a great harmony.

shuffle

Thanks to its exclusive system of measures compatibility, we can make a completely random collocation, combining different widths and lengths, as desired, in a very simple and fast way.

ecology

We are a Company which is committed to environmental care and which respects all types of species. Each year we add new optimizations in our production processes to cooperate with the sustainable protection of the planet and to improve the quality of life of its inhabitants.

Lost French Oak wood floors stand out for their eco-friendly components, since they are produced with ancient barrels in disuse as well as with a plywood of implemented renewable wood.